Abstract

Aerobic granular sludge (AGS) was preserved using an agar embedding method to maintain its stability. No obvious damage was imposed on the granular appearance during 30 days of cold and dry storage, but the granular microstructure had an uneven surface with a large number of holes. The results were consistent with the extinction of microbial communities and the monitored consumption of extracellular polymeric substances, in which granular specific oxygen utilization rate and mixed liquor volatile suspended solids/mixed liquor suspended solids ratio, respectively, decreased by 72.4% and 62.5% during storage. A mass conversation calculation indicated that the loss of granular mass was 1.6393 g. An offensive odour was smelled during storage, and the results indicated that a material transformation and mitigation were involved between AGS and the gas phase. Although the granular structure was destroyed to a certain extent, no obvious damage was imposed on the granular skeleton during storage. After it was aerated again after a feeding with real wastewater, the residual skeleton served as a carrier for the rapid proliferation of microorganisms, and good granular properties were obtained after 11 days of reactivation.

INTRODUCTION

Aerobic granular sludge (AGS) is a biological polymer that forms through microbial self-coagulation and has many good properties compared with activated sludge (Adav et al. 2008). After more than 20 years of developments, AGS technology has successfully been applied in engineering, albeit only in several reported projects. Limited engineering practice has indicated that civil construction and operational costs could be greatly reduced by using AGS technology (Ni et al. 2009; Long et al. 2015; Pronk et al. 2015; Farooqi & Basheer 2017), which makes it a promising wastewater biological treatment technology. Similar to other bioreactors, there is also an overhaul or idle process for an aerobic granular reactor, in which the granular stability would be affected by changes in the operational conditions. Meanwhile, a harsh environment and long cultivation time are usually needed for aerobic granulation (Adav et al. 2008; Nancharaiah & Kiran 2017). Therefore, the feasibility of storage and reuse of the scarce AGS has drawn attention of researchers because almost no AGS is sold or bought through commercial activities. However, everything is dialectical, and the scarcity of AGS is no exception: it is a valuable resource under proper usage, and it is no more than excess sludge if it is not properly stored.

At present, existing AGS storage strategies include in situ storage and ectopic storage. An idle reactor was directly employed to preserve AGS by in situ storage, and it was found that granules gradually lost their metabolic activity after being stored (Tay et al. 2002; Zhu & Wilderer 2003). Subsequently, it was recognized that the environment led to even worse granular properties (Zhang et al. 2005; Xu et al. 2010; He et al. 2017). Although in situ storage is simple and requires no additional footprint, it is difficult to effectively maintain granular stability. Ectopic storage of AGS includes wet storage and dry storage, in which granules usually need to be pretreated before storage. In addition, the difference between granular wet storage and dry storage was whether there was an obvious water phase in the storage system. Room-temperature wet storage was the simplest ectopic storage to preserve AGS, but no obvious improvement was achieved compared with in situ storage, where a decline in granular structural integrity and different degrees of metabolic activity were observed (Gao et al. 2012; Yuan et al. 2012).

Since endogenous respiration of microorganisms at room temperature is obvious, storing granules at low temperature was investigated. Among them, storage by fresh water or tap water at 4 °C or 8 °C was adopted by many studies, but the results were not consistent. It was found that the granular structural integrity could be successfully maintained by controlling the storage conditions. Gao et al. (2012) reported that there was no obvious change in granular colour and structure when stored in distilled water at 4 °C, but the specific oxygen utilization rate (SOUR) nearly decreased to zero. Wan et al. (2014a) found that granules shrank slightly in 4 °C distilled water, and the granular surface was smooth. In contrast, a decrease in both structural integrity and metabolic activity was observed in similar studies (Zeng et al. 2007; Adav et al. 2009; Tu et al. 2010). In addition to storing granules in cold water, there have also been reports regarding preservation of AGS by freezing, but obvious disintegration occurred during the thawing process or through aeration during reactivation (Lv et al. 2013a; Yan et al. 2017).

Based on fresh water storage, different solutions have been used to preserve AGS. Gao et al. (2012) successfully maintained the granular colour and shape in a glucose solution at 4 °C, but the granules transformed into irregular, brown, flaky, hollow structures at −25 °C. Wan et al. (2014a) found that there was little change in the granular morphology when stored in 3% NaCl solution (4 °C), but the granular surface became rough. Under the same environment, no big changes in granular morphology were observed in an acetone and formaldehyde solution, but granules shrank significantly in an acetone and ethyl acetate solution. In addition to wet storage, explorations of dry storage of AGS have been reported. Lv et al. (2013b) and Hu et al. (2016) found that AGS lost most of the activity after being dehydrated, but no serious damage was imposed on the granular structure.

In conclusion, it has been difficult to maintain granular stability even when the storage process became more complex, and the optimal storage strategy for maintaining granular stability remains to be determined. At the same time, existing studies have mainly focused on the change in the sludge phase, and little attention has been paid to material migration and transformation between different phases. In fact, an offensive odour was discovered in an existing study during wet storage (Gao et al. 2012; He et al. 2017), and the release of pollutants into the liquid phase by AGS was also monitored (Zeng et al. 2007; Xu et al. 2010), which indicated that material migration and transformation was involved during the wet storage process. However, material migration and transformation between AGS and the liquid phase or gas phase suggested a loss of granular mass and energy, which is adverse to the stability of AGS. Interestingly, compared with the long time that is needed for aerobic granulation that is seeded with activated sludge, the stability of the stored AGS could be recovered in 1 day to 3 weeks (Zhang et al. 2005; Zeng et al. 2007; Tu et al. 2010; Gao et al. 2012; Yuan et al. 2012; Lv et al. 2013a, 2013b; Hu et al. 2016; He et al. 2017), indicating that AGS storage technology has good application potential.

The immobilized technique is intended to immobilize specific microorganisms on the selected carrier to maintain a high microbial concentration and biological activity (Ogugbue et al. 2012; Yu et al. 2015), with an ultimate intention to realize rapid microbial proliferation under the appropriate conditions. The agar embedding method is widely used because of its simple procedure and mild operating conditions; the microorganism is in a solid state after being embedded, which provides a new idea for the storage of AGS. Until now, there have been few reports on the storage of AGS preserved using the embedding method. To overcome the granular stability loss that is caused by material migration and transformation between AGS, the liquid phase and the gas phase during wet storage of AGS, the embedding method was employed to simplify the storage environment into two phases (a solid and gas phase). This was done to effectively preserve AGS. Variation in the granular mass was investigated during storage and mechanism of AGS stability loss was explored, which provides theoretical support for green preservation and the effective utilization of AGS.

MATERIALS AND METHODS

Storage of AGS

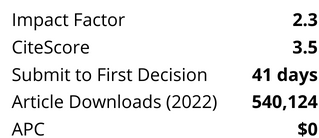

Approximately 15.6 L AGS mixed liquid was collected from a lab-scale sequencing batch reactor (SBR, notated as R1 with exchange ratio of 60%, height of 200 cm, inner diameter of 10.5 cm and working volume of 15.6 L) that continuously operated for 3 months. The reactor was fed with simulated wastewater; the influent quality was: chemical oxygen demand (COD) 600 mg/L, total inorganic nitrogen (TIN) 40 mg/L, ammonia nitrogen (NH4+-N) 40 mg/L and total phosphorus (TP) 6 mg/L. The average COD volume load was 2.4 kg/m3 · d. The cycle time of R1 was 6 hours (4 cycles per day), which included filling (3 min), the aerobic reaction (354 min), settling (1 min) and discharge (2 min). Compressed air was pumped into the reactor using an electromagnetic air pump, and the superficial gas velocity was between 1.2 and 1.5 cm/s. The mixed liquor was sieved through a 0.3 mm sieve, where AGS above the 0.3 mm sieve was collected and washed three times with tap water. Then, the AGS was embedded in a 3.0% agar solution under 80 °C in three unique culture dishes (inner diameter 12.5 cm, height 1.25 cm) for observation (Figure 1) and an open container (inner diameter 14 cm, height 20 cm and effective volume 2.08 L) for reactivation, where the AGS concentration in the agar block was approximately 30 g/L. Afterward, the blocks were placed in a refrigerator (4 °C) and stored for 30 days after solidification.

The mature AGS that was used for storage was orange with a smooth surface, and its shape was irregular and globular. The granular SV30/SV5 (SV: sludge volume) and sludge volume index (SVI) were 0.95 and 45.87 mL/g, the mixed liquor volatile suspended solids/mixed liquor suspended solids (MLVSS/MLSS) was 0.56, the extracellular polymeric substances (EPS) and polysaccharides/proteins ratio (PN/PS) were 129.54 mg/g MLSS and 0.55, SOUR and SOURH/SOURN were 37.14 mg O2/(g MLSS h) and 5.59, and the granulation rate and average particle size were 92.79% and 1.87 mm, respectively.

Reactivation of AGS

Equipment and operation

The agar block in the open container (effective volume of 2.08 L) was taken out from the refrigerator after it was stored for 30 days, and was manually cut into small blocks for subsequent processing. Then, all of the agar blocks (granular concentration of approximately 30 g/L) in the container were heated for 1.5 hours at 40 °C in a thermostatic water bath to remove part of the agar solution. Afterward, the remaining mixture was inoculated into an SBR (nominated as R2; its configuration was the same as R1) for reactivation, which was broken into pieces by aeration. In addition to the influent quality, the operational parameters of R2 were identical to those of R1.

Media

The influent was septic tank sewage from an office building. The wastewater quality was as follows: COD 534.96–810.32 mg/L, total nitrogen (TN) 58.72–86.06 mg/L, NH4+-N 48.96–73.92 mg/L and TP 4.94–11.87 mg/L. The average COD volume load was approximately 2.69 kg/m3 · d.

Analytical methods

COD, NH4+-N, nitrate, nitrite, TP, pH, SV, SVI, MLSS and MLVSS were determined according to Standard Methods (2005). The size distribution was measured using the wet sieving separation method. Then, 300 mL sludge samples were extracted and filtered through a series of standard sieves with apertures of 4.0 mm, 3.0 mm, 2.0 mm, 1.43 mm, 1.0 mm, 0.6 mm and 0.3 mm. Sludge components that passed through a 0.3 mm sieve and that was retained on each sieve were collected, dried and weighed as Mx (including M4, M3, M2, M1.43, M1, M0.6, M0.3 and M0-0.3). The size distribution was obtained by recording the mass percentage of sludge within a certain size range (such as 0.3–0.6 mm) compared with the entire sludge sample (MT = M0-0.3 + M0.3 + M0.6 + M1 + M1.43 + M2 + M3 + M4), which was calculated using (Mx × 100 ÷ MT). The granulation rate was the mass percentage of AGS relative to the entire sludge sample, which was calculated using: (M0.3 + M0.6 + M1 + M1 + M1.43 + M2 + M3 + M4) × 100 ÷ MT. The average particle size was the diameter when the proportions of filtered sludge and unfiltered sludge were both 50%, which was calculated from the mass distribution curve. The heat extraction method was adopted to extract EPS from AGS, as suggested by Adav & Lee (2008). The PS content was determined using the phenol-sulphuric acid method (Gerhardt et al. 1994). The PN content was analysed using the modified Lowry method (Lowry et al. 1951). EPS was the sum of PS and PN. The (SOUR)H produced by heterotrophic bacteria and specific oxygen utilization rates produced by ammonium oxidizers and nitrite oxidizers, namely, (SOUR)NH4 and (SOUR)NO2, were determined using the methods developed by Ochoa et al. (2002). The sum of (SOUR)NH4 and (SOUR)NO2 was used to represent the overall activity of nitrifying populations, namely, (SOUR)N. The granular morphology and elemental composition were qualitatively observed using a scanning electron microscope (SEM, FEI, MLA650F, USA) and an energy disperse spectroscopy (EDS, BRUKER, QUANTAX, Germany), respectively, and granular samples were prepared using the method suggested by Tay et al. (2001).

RESULTS AND DISCUSSION

Storage of AGS

Morphological changes of AGS during storage

After 30 days at low temperature in dry storage, most of the granules remained light yellow, except for obvious black anaerobic cores that occurred inside a few large granules (Figure 2). Most of the granules maintained good structural integrity, but their appearance was not as good as that of the mature granules, which became rather rough. Wet storage is adopted by most granular storage studies, and a black colour and disintegration of AGS are usually observed due to endogenous respiration during the storage process (Zhu & Wilderer 2003; Zeng et al. 2007; Gao et al. 2012; He et al. 2017). In other dry storage, it has been found that AGS shrinks and blackens (Lv et al. 2013b; Hu et al. 2016). In contrast, obvious deteriorations in the granular colour and structure were observed when using agar embedding storage. However, there was no rough appearance, which indicated that AGS could be preserved by the agar embedding system.

Variations of granular microstructure during storage

The microstructure of AGS was observed by SEM. It was found that the mature AGS (Figure 1) was dense in structure and contained a large number of bacilli, where microbes were tightly bound to each other and were surrounded by a large amount of inert substances. In contrast, the stored AGS (Figure 2) had an uneven surface with a large number of holes, and the number of observed microbes decreased significantly. These results also explained why the granular surface was rough.

Mass conservation of the agar block

The mass change of the storage system was calculated according to mass of the input material, water content of the agar blocks, and so on (Figure 3), and it was assumed that the agar could not be degraded by the microbes in the storage system. It was found that the mass loss of the agar block was 17.55 g, comprising 15.9107 g water loss and 1.6393 g granular loss. As offensive odour was smelled during storage; it was speculated that the granular mass loss was caused by microbial respiration, which eventually led to the release of gaseous products. Odour release during storage has also been reported in other studies (Gao et al. 2012; He et al. 2017). Therefore, in addition to material transformation inside the agar system, there was also material mitigation between AGS and the gas phase, which is an environmental risk that cannot be ignored in application.

Reactivation of AGS

Morphological changes of AGS

A large amount of granular breakage was observed after the stored AGS was aerated (Figure 4). As such, a large number of broken granules and flocculated sludge appeared in the reactor on the first day, and a small number of large black granules were observed in the mixed liquid. Then, most of the flocculent sludge was discharged from the reactor after a short settling time in the subsequent two days, which led to a significant decrease in the proportion of the flocculent sludge. However, abundant flocculated sludge appeared in the reactor again on the fourth day. After 5 days of repeated selection, AGS began to become dominant on the ninth day. AGS was obviously yellow with a smooth appearance and dense structure on the eleventh day. The microstructure of reactivated AGS was observed by SEM. It was found that a large number of holes that had formed during storage disappeared during the reactivation stage, and were replaced by massive, tightly adhered microorganisms with an inert substance wrapped around them.

Variations of granular elemental composition

Elemental compositions of mature AGS, stored AGS and reactivated AGS were analysed by EDS (Table 1). The proportions of C, N, O, S and other organic elements decreased significantly during storage, but the proportions of Na, K, Ca, Mg, Fe and other inorganic compound elements obviously increased. According to the experimental data, the EPS content of AGS that was stored for 30 days was 18.46 mg/g MLSS, which decreased by 86% compared with that of the AGS before storage (129.54 mg/g MLSS). The results were consistent with the disappearance of a large number of microbes (observed by SEM), which is also consistent with EPS consumption as a carbon source in other storage studies (Tu et al. 2010; Xu et al. 2010; Gao et al. 2012). Compared with the elemental composition of stored AGS on the 30th day, proportions of organic elements (such as C, N, O and S) increased during the reactivation stage, which were close to that of mature AGS; however, proportions of most inorganic elements (such as Na, Mg, Cl, K, and Fe) decreased. The results were consistent with the proliferation of microbes and secretion of EPS (granular EPS on the 11th day was 49.56 mg/g MLSS) during the reactivation stage. Since the wastewater quality was significantly different between R1 and R2, the elemental compositions of mature AGS and reactivated AGS were not the same, which was the result of biological selection (Liu et al. 2005).

Variations in granular elemental composition

| Stage . | Time . | Elemental composition of AGS (%) . | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C . | N . | O . | Na . | Mg . | P . | S . | Cl . | K . | Ca . | Fe . | Cu . | ||

| Storage | 0 d | 48.12 | 4.56 | 34.36 | 0.14 | 0.17 | 2.94 | 0.50 | 0.35 | 7.0 | 0.91 | 0.34 | 0.62 |

| 30 d | 8.18 | 3.0 | 19.54 | 0.50 | 0.36 | 16.13 | 0.20 | 0.26 | 47.86 | 2.62 | 1.19 | 0.17 | |

| Reactivation | 11 d | 36.29 | 11.84 | 24.79 | 0.43 | 0.26 | 7.16 | 0.37 | 0.07 | 14.70 | 3.35 | 0.16 | 0.56 |

| Stage . | Time . | Elemental composition of AGS (%) . | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C . | N . | O . | Na . | Mg . | P . | S . | Cl . | K . | Ca . | Fe . | Cu . | ||

| Storage | 0 d | 48.12 | 4.56 | 34.36 | 0.14 | 0.17 | 2.94 | 0.50 | 0.35 | 7.0 | 0.91 | 0.34 | 0.62 |

| 30 d | 8.18 | 3.0 | 19.54 | 0.50 | 0.36 | 16.13 | 0.20 | 0.26 | 47.86 | 2.62 | 1.19 | 0.17 | |

| Reactivation | 11 d | 36.29 | 11.84 | 24.79 | 0.43 | 0.26 | 7.16 | 0.37 | 0.07 | 14.70 | 3.35 | 0.16 | 0.56 |

Properties of AGS

Settling properties

There were no large changes in SVI and SV30/SV5 during the reactivation process (Figure 5(a)). SVI was between 20.20 and 29.13 mL/g, and SV30/SV5 remained above 0.94. The results indicated that the AGS had good settling performance, which also showed that 30 days of storage of AGS using the embedding method had little influence on the granular settlement.

Variations in sludge properties during reactivation: (a) SVI and SV30/SV5, (b) MLSS and MLVSS/MLSS, (c) EPS and PN/PS, (d) granulation rate and average particle size, (e) size distribution and (f) SOUR and SOURH/SOURN.

Variations in sludge properties during reactivation: (a) SVI and SV30/SV5, (b) MLSS and MLVSS/MLSS, (c) EPS and PN/PS, (d) granulation rate and average particle size, (e) size distribution and (f) SOUR and SOURH/SOURN.

MLSS and MLVSS/MLSS

No large changes in MLSS were monitored during the reactivation process, which was between 3.51 and 4.51 g/L (Figure 5(b)). The two fluctuations in MLSS were caused by two obvious disintegrations of AGS during the study period. The overall profile of MLVSS/MLSS increased (0.21–0.45), which indicated that microorganisms proliferated quickly during the reactivation process.

EPS and PN/PS

The overall profile of EPS increased during the first 7 days (15.43–46.87 mg/g MLSS), and then it gradually stabilized and remained between 42.99 and 49.56 mg/g MLSS (Figure 5(c)). The results were consistent with increasing EPS profiles produced by other storage studies (Gao et al. 2012; Hu et al. 2016), which indicated that EPS was beneficial to the structural stability of AGS. The overall profile of PN/PS decreased during the first 8 days, and then stabilized and remained between 0.25 and 0.29. As granules recovered with the rapid increase in PN content, the results indicated that PS played a more important role in the structural stability of AGS.

Granulation rate and average particle size

The granulation rate was stable in the first 5 days (82.63–84.15%), which indicated that the disintegration and granulation of AGS were basically in a dynamic equilibrium state during the study period (Figure 5(d)). Then, the granulation rate continued to increase (88.64–93.44%) in the subsequent days, which indicated that the aerobic granulation process gradually dominated in the reactor. Although some AGS disintegrated into flocculent sludge during the reactivation process, flocculent sludge was soon discharged from the reactor under high hydraulic selection pressure (Liu et al. 2005), such that the AGS was dominant in the reactor. The average particle size increased from 1.70 mm to 1.95 mm in the first 3 days, which was due to the increase in the proportion of granules between 1.43 and 3 mm (Figure 5(e)). The average particle size suddenly decreased to a minimum of 1.42 mm on the fifth day, which was mainly caused by the decrease in the proportion of granules between 2 and 3 mm; the results were consistent with the increase in flocculated sludge in the reactor on that day. Then, the overall profile of the average particle size increased (1.78–2.13 mm) as aerobic granulation dominated in the reactor.

SOUR and SOURH/SOURN

The overall profile of SOUR increased (10.25–57.78 mg/O2 · g MLSS h) in the first 9 days, and remained between 50.49 and 54.37 mg/O2 · g MLSS h in subsequent days (Figure 5(f)), indicating that the activity of AGS could be recovered in a few days. The overall profile of SOURH/SOURN decreased (7.98–2.17) in the first 6 days. Then, it gradually stabilized in the following days and remained between 2.33 and 3.23. The results indicated that the proportion of nitrifying bacteria increased significantly during the reactivation process.

Reactor performance

COD and TP removal

The effluent COD reached a maximum of 334.42 mg/L on the second day, and the corresponding COD removal rate reached a minimum of 47.18% (Figure 6(a)). Then, the overall profile of effluent COD decreased (204.13–54.87 mg/L), and the overall profile of the COD removal rate increased (61.84–93.23%). The overall profile of effluent TP decreased (6.31–0.62 mg/L), and the overall profile of the TP removal rate increased (25.06–93.33%) (Figure 6(b)). The removal effect of TP fluctuated in the first 6 days because two disintegrations of AGS led to instability of the system and there was microbial discomfort caused by fluctuations in the water quality.

Profile of reactor performance during reactivation: (a) effluent COD and its removal rate, (b) effluent TP and its removal rate and (c) effluent TN, NH4+-N, nitrate, nitrite and removal rate of TN.

Profile of reactor performance during reactivation: (a) effluent COD and its removal rate, (b) effluent TP and its removal rate and (c) effluent TN, NH4+-N, nitrate, nitrite and removal rate of TN.

Nitrogen removal

No obvious changes in effluent TN were monitored in the first 6 days, which remained between 11.11 and 20.17 mg/L (Figure 6(c)). Then, the effluent TN increased quickly and eventually stabilized, remaining between 43.16 and 46.92 mg/L from the ninth day. The overall profile of effluent ammonia nitrogen decreased and it gradually stabilized to between 5.78 and 6.57 mg/L from the sixth day onward. There was no obvious accumulation of effluent nitrite, and it was always below 1.52 mg/L. Nitrate was maintained at a lower level (0.76–3.55 mg/L) in the first 5 days, but it accumulated significantly from the sixth day onward, and stabilized between 34.77 and 38.34 mg/L after the ninth day. The profile of effluent TN and ammonia nitrogen were similar during the first 5 days, and the TN removal rate was always greater than 75% without obvious accumulation of nitrate and nitrate. The results indicated that denitrification was mainly ascribed to the assimilation effect due to a large number of microbial proliferations during the first 5 days. Afterward, simultaneous nitrification and denitrification dominated in the reactor due to the enrichment of nitrifying bacteria. However, an adverse denitrification effect was achieved due to the lack of an available carbon source, and the TN removal rate gradually decreased to less than 50% as large amounts of nitrate accumulated in the reactor.

Mechanism of granular stability during storage and reactivation

It was shown that there was a large number of functional bacteria inside the stable AGS (Adav et al. 2010), and a unique stratified structure was usually formed (Zheng et al. 2006). However, most of the aerobic bacteria died due to a lack of available nutrients after 30 days in an anoxic and famine-induced environment, such that the SOUR and MLVSS/MLSS of the stored AGS decreased significantly (10.25 mg O2/g MLSS h, 0.21) compared with that of mature AGS (37.14 mg O2/g MLSS h, 0.56). Furthermore, there were indications that some facultative or anaerobic bacteria survived, according to SOUR data. The surviving microorganisms degraded the EPS to obtain energy (Adav et al. 2009; Xu et al. 2010; Tu et al. 2010; Gao et al. 2012; He et al. 2017), which led to a significant decrease in the EPS content and the formation of a rough granular surface. Although the structure of AGS was destroyed to a certain extent, no obvious damage was imposed on the granular skeleton. After the stored AGS was aerated again in the reactor, microorganisms proliferated rapidly on the skeleton (Lettinga et al. 1980), and the increases in MLVSS/MLSS (0.21–0.45) and SOUR (10.25–57.78 mg O2/(g MLSS h)) were monitored. Meanwhile, coagulation between cells was promoted by the secretion of a large number of EPS by the microorganisms, which successfully realized granular reactivation in 11 days (Figure 7).

Mechanism of granular stability during storage and reactivation: (a) mature AGS; (b) AGS-agar block; (c) granules after stored 30 days; (d) AGS reactivated on the 11th day.

Mechanism of granular stability during storage and reactivation: (a) mature AGS; (b) AGS-agar block; (c) granules after stored 30 days; (d) AGS reactivated on the 11th day.

Agar is a stable embedding agent, and its solution is clear, which is suitable for observing the microbial community after solidification. Therefore, the agar embedding method is widely used in microbial culture medium preparation, which has been proven to be effective in maintaining the activity of microorganisms or enzymes. Different from the preparation of the agar medium, no external nutrient was added in the experiment with an aim to preserve the AGS with minimal material input. It was reported that the extinction of microbial communities usually occurred during storage (Adav et al. 2009; Lv et al. 2013a, 2013b; Wan et al. 2014a, 2014b; He et al. 2017), and even a SOUR value of zero was measured (Gao et al. 2012). However, the SOUR of the stored AGS remained above 10 mg O2/g MLSS h, which indicated that the agar embedding method could maintain microorganism activity to a certain extent. Compared with wet storage of AGS, dry storage of AGS was achieved through the agar embedding method, which has practical significance to the circulation of AGS. In addition, the storage environment was simplified to gas and solid phases using the agar embedding method, which makes it convenient to establish the mass conservation of the storage system between gas and solid phases during static storage. These results provide a good foundation to systematically explore the microbial metabolic mechanism.

CONCLUSION

Dry storage of AGS was realized using an agar embedding method, in which the granular structural integrity and metabolic activity were maintained to a certain extent. It was found that a large number of bacteria died and EPS was consumed during 30 days of cold storage, and material transformation and mitigation were involved between AGS and the gas phase. However, no obvious damage was imposed on the granular skeleton, and the skeleton served as a carrier for the rapid proliferation of microorganisms after it was aerated again, successfully realizing granular activation within 11 days.

ACKNOWLEDGEMENTS

This research was supported by Science and Technology program of Education Department of Jiangxi Province (GJJ150627) and Natural Science Foundation of Science and Technology Department of Jiangxi Province (20181BAB216026).

%20cropped.png?versionId=5950)