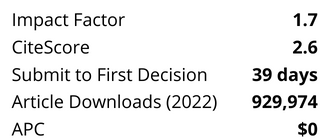

Abstract

A multilayer polyelectrolyte ceramic membrane using LbL was assembled to test the performance of water disinfection capability. The natural raw clay material (kaolin) was used as the main ceramic membrane (CM) support. The impact of the number of polyelectrolyte bilayers (2, 4, 6) on the retention of Escherichia coli was systematically investigated. Test results showed the water permeability coefficients (Lp) were 85.3 L/m2.h.bar and 69.5, 28.3, 50.1 L/m2.h.bar for pristine (CM0) and ceramic membranes with two bilayers (CM2), four bilayers (CM4), and six bilayers (CM6), respectively. Complete retention of E. coli was achieved by the multilayer polyelectrolyte ceramic membrane with four bilayers. The surface morphology of the multilayer polyelectrolyte ceramic membrane was identified by scanning electron microscopy (SEM). The results showed that the multilayer polyelectrolyte ceramic membrane can be safely applied in providing water disinfection.

HIGHLIGHTS

Kaolin ceramic membrane was modified by layer-by-layer assembly up to six bilayers.

The lowest permeability coefficient was obtained for four-bilayer ceramic membrane as 28.3 L/m2.h.bar.

E. coli was completely rejected by the multilayer polyelectrolyte ceramic membrane with four bilayers.

SEM results showed that kaolin ceramic membrane was successfully coated with polyelectrolytes.

Graphical Abstract

INTRODUCTION

Rapid population growth and industrialization have increased the requirement for clean water. Therefore, the need for and accessibility of clean, safe, and healthy water is increasing day by day (Okello et al. 2015). Surface water and groundwater can be contaminated by pathogens due to poor sanitation and hygiene. The drinking of contaminated water often causes waterborne disease, resulting in health symptoms such as diarrhea, vomiting, and gastroenteritis (Pooi & Ng 2018). Especially, Escherichia coli, Enterococcus, Cryptosporidium, and rotavirus mainly cause the majority of diarrhea cases in developing countries (Efstratiou et al. 2017; WHO 2017). Therefore, numerous water decontamination methods and technologies have been developed through extensive research to obtain clean water (Pooi & Ng 2018).

Water disinfection is used to kill pathogens and several conventional methods such as chlorination, ozonation, and ultraviolet treatment are applied extensively. However, these methods have some limitations. For example, chlorination forms carcinogenic disinfection by-products and it can be ineffective for highly resistant waterborne pathogens in some cases (Shannon et al. 2008). Ozonation, which is another disinfection method, forms fewer by-products but has a higher cost than chemical disinfection. Moreover, ozonation can initiate harmful bromate formation when ozone reacts with bromide ions in water (von Gunten 2003). Ultraviolet light in UV-C band (200–280 nm) treatment does not leave residues in treated water like ozone treatment and therefore does not protect against re-infection in the distribution network. Therefore, UV is often used prior to chlorination due to its high oxidizing capability both to obtain high water quality and to reduce the chlorine dosage required (Gray 2013). New approaches are required to improve water quality prior to disinfection, thereby increasing effectiveness and lowering the risk of by-product formation or ineffectiveness.

Many new methods, as well as traditional disinfection methods such as chlorine, chlorine dioxide, ozone, and UV radiation have been used in disinfection so far. Over the past two decades, metal oxide nanoparticles (MeO-NPs) have become an attractive alternative source for disinfection of microbes (Dizaj et al. 2014; Raghunath & Perumal 2017). For example, titanium dioxide (TiO2) (Laxma Reddy et al. 2017), zinc oxide (ZnO) (Zhang et al. 2011), copper (Cu) (Armstrong et al. 2016), molybdenum disulfide (MoS2) (Liu et al. 2016), silver (Ag) (Lalley et al. 2014), iron (hydr)oxide semiconductors (Ruales-Lonfat et al. 2015), and chitosan-based nanocomposites (Motshekga et al. 2015) have been used extensively and they are considered as good antibacterial agents. Moreover, electrochemical treatment, solar light, UV/H2O2 and photo-Fenton treatment (UV–Vis/H2O2/Fe2+,3+) have also been applied for water disinfection (Feng et al. 2004; Kraft 2008; Gosselin et al. 2013; Rubio et al. 2013).

The development of new methods is a major challenge. When the limitations of traditional disinfection methods are considered, membrane processes offer new approaches for water disinfection without the formation of disinfection by-products (Regula et al. 2014). Ultrafiltration membranes can provide physical disinfection. The various polymeric membranes have some drawbacks such as organic or inorganic foulant accumulation on the membrane surface, low flux, frequent backwashing requirement, etc. (Zielińska & Galik 2017). However, ceramic membranes have several advantages such as good thermal and chemical stability, high flux, high resistance to corrosion, less fouling/scaling rates, high efficiency of backwashing, and longer membrane life compared with polymeric membranes (He et al. 2019; Issaoui & Limousy 2019; Li et al. 2020).

Despite these advantages of the ceramic membranes, they require some modifications to improve some of their properties. Layer by layer (LbL) stands out as an effective and simple modification method to fabricate selective membrane layers (Dizge et al. 2018). The LbL assembly method is a cyclic process in which polycations and polyanions in the solution are applied to a substrate in sequence from bottom to top. At each stage, rinsing is done to remove weakly associated polymers (Richardson et al. 2015; Xu et al. 2015). Polyelectrolyte multilayer (PEM) assembly is driven by electrostatic interactions between oppositely charged polyelectrolytes (Ariga et al. 2007).

A tubular ceramic macroporous substrate has been modified by the spray-LbL assembly method to build multilayers (Tang et al. 2013). Poly(ethyleneimine) (PEI)/poly(acrylic acid) (PAA) with a five-bilayer composite membrane rejected over 99% of the acid fuchsin, congo red, and methyl blue organic dyes. A metal–organic framework (MOF) hybrid membrane and ZIF-8/PSS has been fabricated on a tubular alumina substrate through a layer-by-layer self-assembly technique by Wang et al. (2016). They reported that the prepared membrane showed nanofiltration properties and 98.6% of methyl blue was rejected with the flux of 21 L/m2 h bar under optimized conditions.

The World Health Organization (WHO) has declared that all water for human consumption should contain zero CFU (colony forming units) of E. coli per 100 mL of sample. Many physical and chemical processes such as the use of membrane filtration, free chlorine as well as ozone, and ultraviolet radiation have been proposed and these processes are used intensively. However, some of these processes can cause undesirable health effects in humans. In this study, we investigated a process using a multi-layered polyelectrolyte ceramic membrane to remove E. coli from a model solution, which may be an alternative to chemical treatment. For LbL assembly, polycationic poly(diallyldimethylammoniumchloride) (PDADMAC) and polyanionic poly (sodium 4-styrenesulfonate) (PSS) were used as two strong oppositely charged polyelectrolytes and they were applied on a kaolin-based ceramic membrane support. The prepared multilayer polyelectrolyte ceramic membrane was tested for water disinfection ability.

MATERIALS AND METHODS

Materials and chemicals

The kaolin was used to prepare the membrane support and it was kindly provided by NG Kütahya Ceramic, Kütahya, Turkey. The kaolin was sieved through a 325-mesh screen to obtain <45 μm kaolin powder. Starch was purchased from a local market. Poly(diallyl dimethyl ammonium chloride) (PDADMAC, 20 wt%) (cationic polyelectrolyte), poly(sodium styrene sulfonate) (PSS, powder) (anionic polyelectrolyte), calcium carbonate and methocel were supplied from Sigma-Aldrich. The polyelectrolytes were dissolved in NaCl (Riedel-de Haën) solution (0.2 M) and it was mixed overnight to achieve a homogeneous solution. The solution was used to perform LbL self-assembly at the washing step. All chemicals were analytical grade.

Preparation of the ceramic membrane support

The detailed description of the experimental procedures for ceramic membrane support preparation can be found elsewhere (Boussemghoune et al. 2020). The kaolin (70%), calcium carbonate (25%), starch (2%), and methocel (3%) were mixed and 3.5 g mixed powder was weighed. Then, the powder was poured into the press mold with a diameter of 4 cm and manual hydraulic pressing (MSE Technology) was applied to reach six tons of pressure. After the pressing step, circular ceramic membrane supports were put into the sintering tables and they were placed into the oven for the sintering process. The details of the sintering procedure have been described in our previous study (Boussemghoune et al. 2020). The temperature was increased at a heating rate of 2 °C/min up to 250 °C and then the temperature was increased at a heating rate of 5 °C/min from 250 to 1,200 °C. Finally, the supports were left to cool spontaneously up to room temperature. The photographs of the ceramic membrane support after sintering are shown in Figure 1.

The photographs of ceramic membrane support: (a) top view and (b) cross-view.

Preparation of multilayer polyelectrolyte ceramic membrane

A detailed explanation of the LbL assembly method, which was also used in this study, was reported by Dizge et al. (2018). A schematic procedure of two-bilayer LbL self-assembly is given in Figure 2. The ceramic membrane supports were washed twice with deionized water to remove impurities. An aqueous solution of PDADMAC and PSS with 500 mg/L polyelectrolyte concentration was treated sequentially with the ceramic membrane support for 10 min. The pH of the polyelectrolyte solutions was 6.8 and the membranes were agitated gently in an orbital shaker at 50 rpm. All the multilayer polyelectrolyte ceramic membranes were prepared at a room temperature of 25 ± 1 °C. Excess polyelectrolytes were removed from the support surface between each treatment using an NaCl solution (0.2 M) for 5 min. After this stage, an initial electrostatically self-gathered bilayer (single-cationic and single-anionic layer) was formed. Two, four, and six bilayers were obtained by repeating the stages depicted above. PDADMAC-PSS multi-layered ceramic membranes with two, four, and six bilayers were named CM2, CM4, and CM6, respectively. The multilayer polyelectrolyte ceramic membranes were used for water disinfection.

Performance tests of multilayer polyelectrolyte ceramic membranes

After the pure water flux experiments, Gram-negative E. coli ATCC25922 bacteria filtration experiments were carried out under 2 bar pressure. The used E. coli suspensions in water had a concentration of 2 × 107 CFU/mL and 100 mL of the bacteria culture was filtered through the ceramic membranes. The detailed description of the experimental procedures for E. coli culture inoculation and measurement studies can be found in Ozay et al. (2016). The growth curve of E. coli culture was achieved by counting bacteria in Petri dishes. A liquid culture medium was prepared for growth of E. coli bacteria using nutrient broth (Merck). E. coli bacteria cells were inoculated in 50 mL of solution containing nutrient broth and incubated at 35 °C for 24 h. Then, the required amount was taken from this solution containing E. coli bacteria, and added to 1 L of sterile distilled water to provide a quantity of 2 × 107 CFU/mL.

SEM analysis of the multilayer polyelectrolyte ceramic membranes

The surface morphology of the multilayer polyelectrolyte ceramic membranes was characterized by SEM analysis (Zeiss, Supra 55). Before SEM analyses, the membranes were washed twice with deionized water and dried overnight to remove moisture. Carbon tape was used to fix the samples onto stubs. Samples were coated with platinum by low vacuum sputter coating in order to increase the conductivity of the membranes and to obtain high image quality.

RESULTS AND DISCUSSION

Surface morphology of the multilayer polyelectrolyte ceramic membranes

The morphological analysis of the multilayer polyelectrolyte ceramic membranes using SEM is presented in Figure 3. According to the SEM images, some deep cracks were found in the pristine ceramic membrane support (Figure 3(a)). However, deep cracks were still observed for PDADMAC-PSS multi-layered ceramic membranes with two bilayers (Figure 3(b)). The cracks did not appear as the number of polyelectrolyte coating layers increased from two to four bilayers (Figure 3(c)). It was noticed that some places on the multilayer polyelectrolyte ceramic membranes were not covered with polyelectrolyte for six bilayers (Figure 3(d)).

SEM images of multilayer polyelectrolyte ceramic membranes: (a) pristine CM (CM0), (b) CM2, (c) CM4, (d) CM6.

SEM images of multilayer polyelectrolyte ceramic membranes: (a) pristine CM (CM0), (b) CM2, (c) CM4, (d) CM6.

Effect of bilayer number on water permeability coefficients (Lp)

Lp (also called the water permeability coefficient) can define membrane classification. A membrane with Lp ≤ 50, Lp = 50–500, and Lp ≥ 500 L/m2 h bar is classified as a hyperfiltration, ultrafiltration, and microfiltration membrane (Mulder 1991). The pure water permeability using different multilayer polyelectrolyte ceramic membranes is represented in Figure 4. Lp was calculated from the slope of pure water flux versus transmembrane pressure. Lp results showed that water permeability coefficients were 69.5, 28.3, and 50.1 L/m2 h bar for CM2, CM4, and CM6, respectively. However, the Lp value of pristine ceramic membrane (CM0) was 85.3 L/m2 h bar. The prepared multilayer polyelectrolyte ceramic membranes were in a range of ultrafiltration and hyperfiltration. The decrease of Lp value could prove that polyelectrolytes were successfully deposited on the ceramic membrane support. So, the thin polyelectrolyte layer caused a decrease of the pore size of the ceramic membrane up to four bilayers, resulting in lower water flux. However, the Lp value increased for six bilayers but was still lower than for two bilayers. It could be concluded that six bilayers caused increasing ceramic membrane pore size. The reason can be attributed to polyelectrolyte–salt charge neutralization interactions (DuChanois et al. 2019). Therefore, CM4 was chosen for E. coli filtration due to the lower number of bilayers with adequate performance.

Variation of permeate water flux of distilled water versus transmembrane pressure.

Variation of permeate water flux of distilled water versus transmembrane pressure.

Da Silva Biron et al. (2016) used mullite tubular ceramic membranes with an average pore size of 0.39 μm. The flux of distilled water was approximately 190 L/m2.h. A similar result was obtained by Diana et al. (2019). The highest flux was 208 L/m2.h at 1.25 bar when a ceramic membrane with clay:fly ash (60%:40%) was used.

E. coli filtration experiments

Figure 5 shows the fluxes of the CM4. The membrane did not show serious flux decline when E. coli filtration was started. The flux of the multilayer polyelectrolyte ceramic membrane after E. coli filtration decreased from 56.3 to 54.2 L/m2.h after 90 min filtration.

E. coli flux test. Deionized water flux was measured for the first 10 min of filtration, then E. coli solution was filtrated for 90 min, after which time the flux for deionized water filtration was collected for the last 10 min without cleaning.

E. coli flux test. Deionized water flux was measured for the first 10 min of filtration, then E. coli solution was filtrated for 90 min, after which time the flux for deionized water filtration was collected for the last 10 min without cleaning.

E. coli filtration experiments were performed to test the rejection capacity of the multilayer polyelectrolyte ceramic membrane. The bacteria counts in the permeate stream are presented in Table 1. The lowest bacteria counts were found in the permeate for CM4 (1 CFU/mL) when compared with that observed in the permeates from CM2 (1,250 CFU/mL) and CM6 (985 CFU/mL). These results showed that removal of bacteria by CM4 was at least 3 log better than that obtained with pristine ceramic (CM0) and multilayer polyelectrolyte ceramic membranes (CM2 and CM6).

Rejection of E. coli counts using heterotrophic plate count method

| Membrane . | Concentration in feed (Cf)a . | Concentration in permeate (Cp)a . | Removal efficiency . | Log removal (Rlog) . |

|---|---|---|---|---|

| type . | (CFU/mL) . | (CFU/mL) . | R = 1 − Cp/Cr . | Rlog = −log(1 − R) . |

| CM0 | 2.01E + 07 | 2,680 | 0.9998667 | 3.87 |

| CM2 | 2.01E + 07 | 1,250 | 0.9999375 | 4.21 |

| CM4 | 2.00E + 07 | 1 | 0.9999999 | 7.00 |

| CM6 | 2.00E + 07 | 985 | 0.9999507 | 4.31 |

| Membrane . | Concentration in feed (Cf)a . | Concentration in permeate (Cp)a . | Removal efficiency . | Log removal (Rlog) . |

|---|---|---|---|---|

| type . | (CFU/mL) . | (CFU/mL) . | R = 1 − Cp/Cr . | Rlog = −log(1 − R) . |

| CM0 | 2.01E + 07 | 2,680 | 0.9998667 | 3.87 |

| CM2 | 2.01E + 07 | 1,250 | 0.9999375 | 4.21 |

| CM4 | 2.00E + 07 | 1 | 0.9999999 | 7.00 |

| CM6 | 2.00E + 07 | 985 | 0.9999507 | 4.31 |

aThe relative standard deviation for all measurements is within ±5%.

Da Silva Biron et al. (2016) investigated morphological and structural characterization of ceramic membranes of mullite and their application in the removal of E. coli. The filtration experiments using mullite membranes supplied 66% and 98% removal efficiency when pressures of 200 and 50 kPa, respectively, were applied. They reported that the use of mullite membranes showed limited efficiency towards bacteria retention (da Silva Biron et al. 2016). Diana et al. (2019) prepared microfiltration ceramic membrane from mixed clay and fly ash material with pore size 1.6–2 μm and the ceramic membranes were tested to remove E. coli bacteria in water river. The results showed that ceramic membrane with the composition of clay:fly ash (40%:60%) was enhanced up to 99.048% E. coli removal efficiency with 0.25 bar operating pressure (Diana et al. 2019). Commercially available pristine and iron oxide nanoparticle coated ceramic membranes were tested by Karnik et al. (2007). Pristine membrane filtration and ozonation supplied 7 log removal of E. coli as compared with 7.5 log removal with coated membrane filtration and ozonation. The mortality of E. coli in the permeate was 15%, ∼50%, and ∼86% for pristine membrane filtration, ozonation, and combined ozonation–pristine membrane filtration. However, the mortality of E. coli in the permeate was >99% for ozonation-coated membrane filtration (Karnik et al. 2007). In a study by Davies et al. (2010), commercially available ceramic membrane (5 kDa) was coated with iron (Fe2O3) or manganese oxides (MnO2) using the layer-by-layer technique. They reported that these coatings could enhance the performance of the hybrid ozonation–filtration process. Iron oxide coated membrane was enhanced to kill E. coli bacteria and the survival of the bacteria was less than 1%, which was significantly lower than that with the uncoated membrane.

The electrostatic interaction between polyelectrolyte and E. coli occurring on the ceramic membrane is schematically presented (Figure 6). The rejection efficiency of the multilayer polyelectrolyte ceramic membrane increased due to the electrostatic repulsion occurring between the negatively charged E. coli and the negatively charged PSS on the last layer of the membrane.

A schematic illustration of electrostatic interaction between polyelectrolyte and E. coli.

A schematic illustration of electrostatic interaction between polyelectrolyte and E. coli.

CONCLUSIONS

The multilayer polyelectrolyte ceramic membrane was developed using a layer-by-layer self-assembly technique for water disinfection. E. coli was used as an indicator of Gram-negative bacteria. A complete removal of E. coli was obtained by the ceramic membrane with four bilayers. At least 4 log bacteria were removed by CM2 and CM6. Moreover, Lp results showed that the water permeability coefficient for CM4 was at the lowest value (28.3 L/m2 h bar). The prepared multilayer polyelectrolyte ceramic membranes were in a range of ultrafiltration and hyperfiltration. The multilayer polyelectrolyte ceramic membrane can be used to eliminate E. coli from drinking water and domestic wastewater outlets.

DATA AVAILABILITY STATEMENT

All relevant data are included in the paper or its Supplementary Information.

%20cropped.png?versionId=5956)